The alternator is an essential component of a vehicle’s electrical system. It converts mechanical energy into electrical energy to power the car’s electrical systems and recharge the battery. While alternators are designed to last for many years, they can and do fail, leading to a host of potential car problems. Understanding the common issues that can cause alternator failures can help drivers take proactive steps to maintain their vehicles and avoid unexpected breakdowns.

What Is an Alternator?

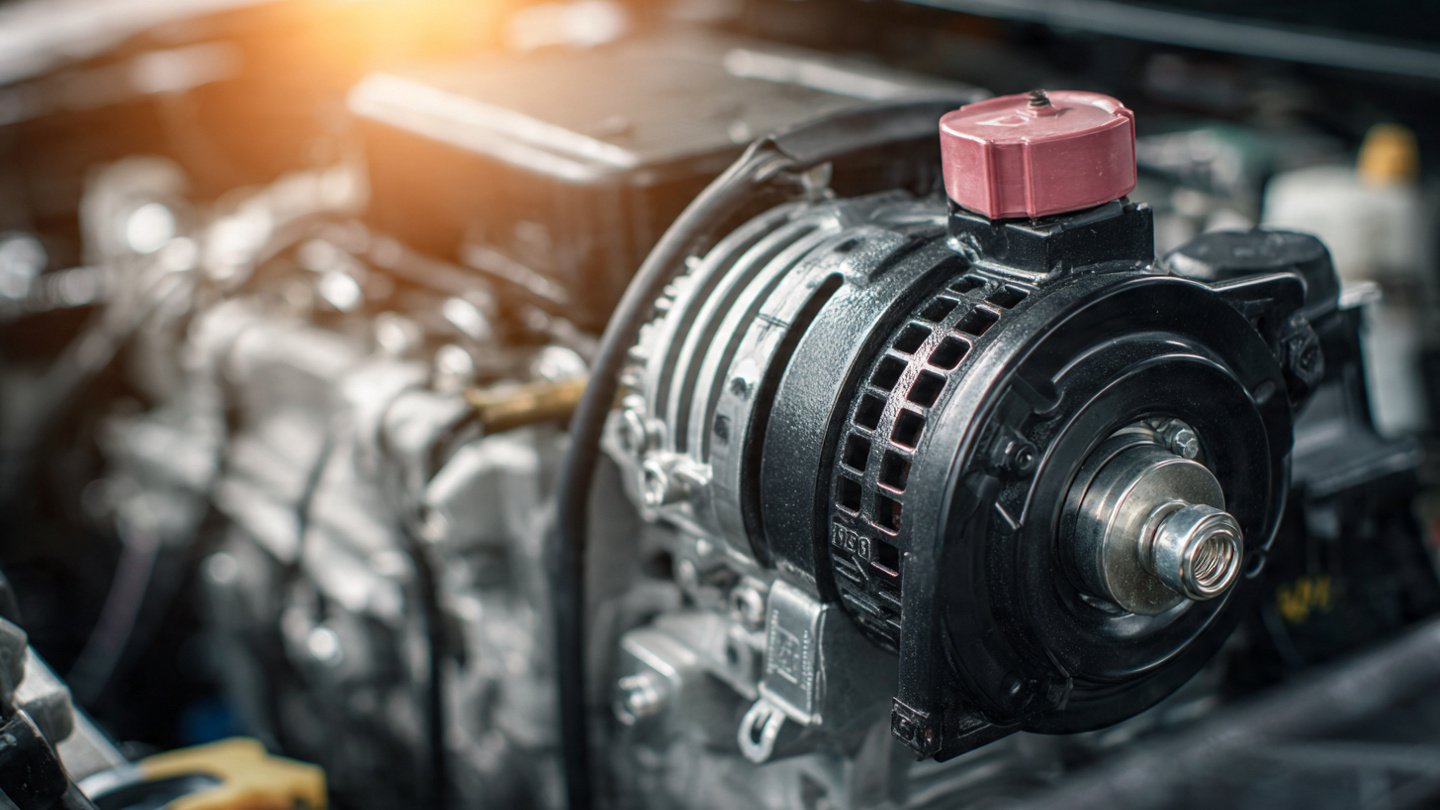

Before diving into the issues and causes of alternator failures, it’s essential to understand what an alternator is and its role in a vehicle. The alternator is a type of generator that produces electricity for the car while the engine is running. It helps charge the battery and powers critical electrical systems such as the lights, radio, and air conditioning.

The alternator typically works in conjunction with the battery; while the battery starts the engine, the alternator takes over as the primary power source as soon as the engine is running. This system helps maintain the vehicle’s electric needs and ensures that the battery remains charged.

Common Symptoms of Alternator Problems

Before delving into specific issues, recognizing the symptoms of alternator failure is crucial. Some common signs include:

- Dimming or Flickering Lights: If the headlights dim or flicker while you’re driving, it may indicate that the alternator isn’t providing enough power.

- Electrical Failures: malfunctions in various electrical components, such as radio or power windows, may suggest alternator issues.

- Warning Light: Most modern vehicles come equipped with a warning light on the dashboard that activates when there’s a problem with the charging system.

- Dead Battery: If the battery repeatedly dies, it could be due to the alternator not charging it properly.

- Strange Noises: A failing alternator may produce a whining or grinding noise, often due to a worn-out bearing.

Common Issues That Cause Alternator Failures

1. Wear and Tear

Like any mechanical part, alternators are subject to wear and tear over time. Components can wear out due to the constant motion and stress of the engine running. Brushes and bearings can lose their effectiveness, resulting in poor electrical output and eventual failure. Regular maintenance checks can help identify these issues before they become severe, extending the life of the alternator.

2. Voltage Regulator Failures

The voltage regulator is a crucial component of the charging system as it controls the amount of voltage produced by the alternator. If the voltage regulator fails, it can result in overcharging or undercharging:

- Overcharging: This can damage the battery and electrical systems, leading to the corrosion of terminals and components.

- Undercharging: A voltage regulator that’s not functioning correctly will not supply enough voltage to keep the battery charged, leading to performance issues.

3. Faulty Wiring and Connections

The wiring and connections between the alternator, battery, and other electrical components are vital for the proper functioning of the charging system. Grounds, connectors, and wires can corrode or become loose over time, leading to poor electrical connections. This can cause:

- Inconsistent voltage output

- Failure to adequately charge the battery

- Short circuits that can damage other electrical components

4. Belt Problems

The alternator is driven by a belt connected to the engine. If the belt becomes worn, loose, or frayed, it may slip or even break, leading to alternator failure. Symptoms of belt issues include:

- Squeaking or squealing noises coming from the engine bay

- Poor acceleration or stalling

- Increased load on the engine, potentially leading to overheating

Regular inspections of your vehicle’s serpentine or accessory belts are essential for preventing these types of problems.

5. Excessive Heat

Heat is a significant enemy of an alternator. Excessive heat can lead to the breakdown of internal components, including insulation, winding, and other electrical parts. Several factors can lead to overheating:

- Poor ventilation: If the alternator is obstructed or its cooling fins are blocked, it may not dissipate heat effectively.

- Overloading: If a vehicle has too many electrical accessories (like aftermarket lights, sound systems, etc.), it can draw more power than the alternator is designed to handle.

6. Age and Condition of the Battery

While the alternator generates electricity, it relies on the battery to store that power. If the battery is old, damaged, or weak, it may not hold a charge effectively. This can lead to:

- Increased load on the alternator as it works overtime to keep the battery charged

- Premature alternator failure due to consistent overworking

Regularly testing the battery’s condition and replacing it when necessary can prevent strain on the alternator.

7. Contamination

Contamination from oil, dirt, or moisture can wreak havoc on alternator performance. If these contaminants enter the alternator through damaged seals or gaskets, they may lead to corrosion of electrical components or bearing failure. Keeping the engine bay clean and ensuring proper seals are intact can mitigate these risks.

8. Manufacturing Defects

Although less common, defects in manufacturing can lead to early alternator failure. This can include poor-quality materials or inadequate assembly practices. Ensuring that replacements are sourced from reputable manufacturers can help avoid encountering these defects.

9. Electrical System Overload

Modern vehicles are loaded with electronic systems that require significant power. As more electronic accessories are added (such as additional lights, sound systems, or navigation systems), the demand on the alternator increases. If the electrical load exceeds the alternator’s output, it can lead to quick burnout. Understanding the power requirements of additional components can aid in choosing the right alternator for your vehicle.

Preventative Measures

To prolong the life of your alternator and mitigate the risks of failure, consider the following preventative measures:

Regular Inspections

Having a qualified mechanic inspect the charging system regularly can help identify issues early. Check belts, wiring, and connections and ensure there are no signs of wear or corrosion.

Battery Maintenance

Regularly test the battery’s condition, replace it as needed, and clean the terminals to ensure solid connections.

Avoid Overloading

Be mindful of the electrical load on the vehicle. If you’re adding new accessories, consider upgrading the alternator to ensure it can handle increased demands.

Cleanliness

Keeping the engine bay clean can prevent dirt and oil contamination from affecting the alternator. Check seals and gaskets to ensure they are intact.

Listen for Unusual Noises

Pay attention to any unusual noises coming from the engine area, which can indicate belt, bearing, or alternator issues.

Use Quality Parts

When replacing any components of the electrical system, sourcing high-quality parts from reputable suppliers can minimize the risk of premature failures.

Conclusion

Understanding the common issues behind car alternator failures can empower drivers to take preventative measures and recognize early warning signs. Through regular maintenance and awareness of the symptoms, you can avoid unexpected breakdowns and extend the lifespan of your vehicle’s alternator. Whether you’re a car enthusiast or simply a responsible vehicle owner, being informed about the alternator’s function and potential problems is crucial for keeping your vehicle running smoothly. By staying vigilant and addressing issues as they arise, you can maintain a reliable and efficient vehicle for years to come.