The alternator is a critical component of a vehicle’s electrical system, responsible for converting mechanical energy into electrical energy to power the vehicle’s systems and recharge the battery. Despite its importance, alternators can fail, leading to various performance issues. Understanding the common causes of alternator failures can help vehicle owners maintain their cars better and avoid breakdowns. In this article, we’ll explore the main issues behind alternator failures, signs of trouble, and preventative measures.

How the Alternator Works

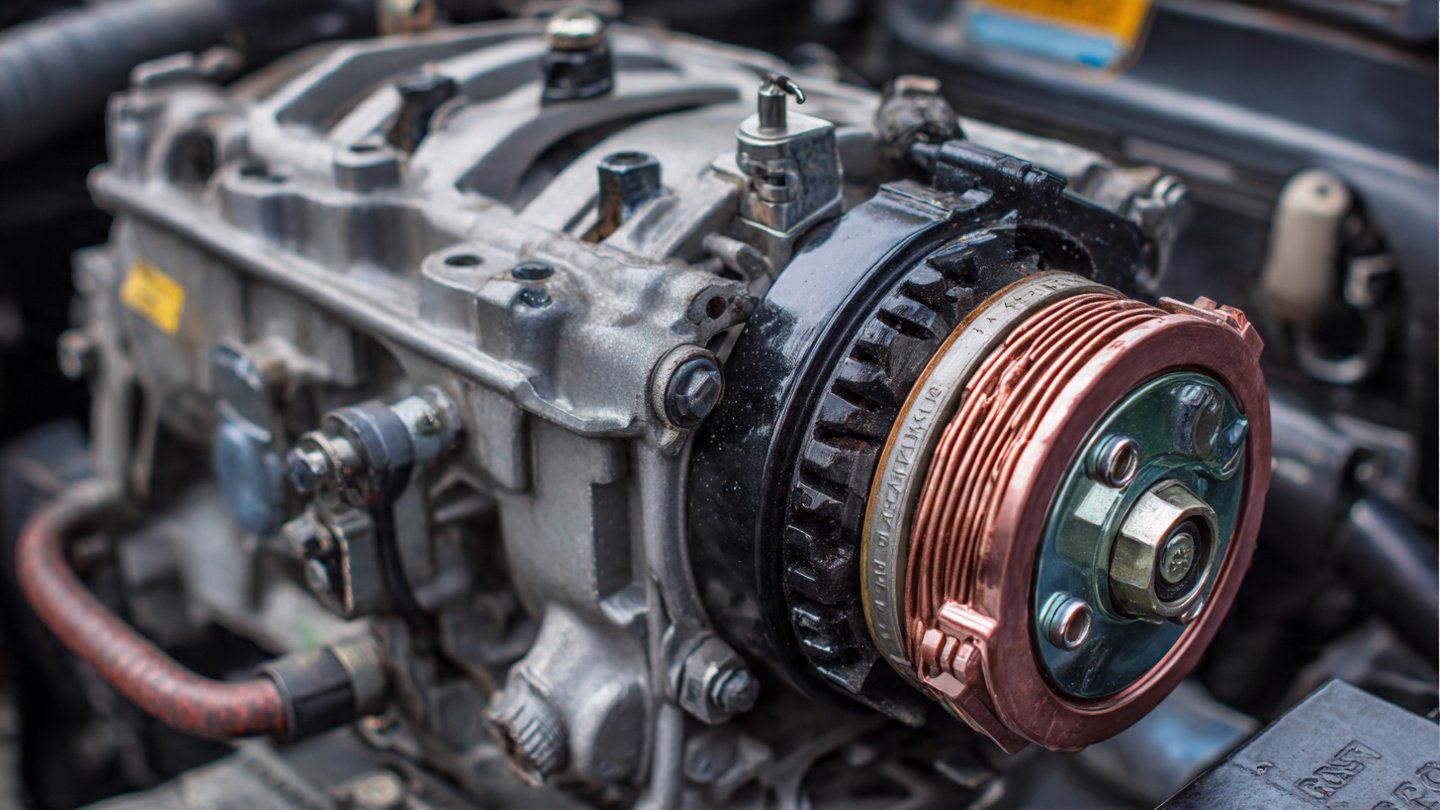

Before diving into the common causes of alternator failures, it helps to understand the basic operation of the alternator. It’s typically driven by a belt connected to the engine. As the engine runs, it turns the alternator’s rotor within its stator, creating a magnetic field. This magnetic field induces electrical current, which is then regulated and distributed to the vehicle’s electrical systems and the battery.

Components of an Alternator

- Rotor: The rotating component that creates a magnetic field.

- Stator: The stationary part that houses winding wire and converts the magnetic energy into electrical energy.

- Rectifier: Converts AC (alternating current) generated into DC (direct current) to charge the battery.

- Voltage Regulator: Ensures the right voltage is delivered to the battery and other electrical systems, preventing overcharging or undercharging.

Common Causes of Alternator Failures

1. Worn Out Bearings

One of the most frequent reasons alternators fail is worn-out bearings. Bearings support the rotor and allow it to spin smoothly. If these bearings wear down, it can create friction, generating excessive heat and leading to alternator failure. Symptoms of bearing failure may include unusual noises, such as grinding or whining, coming from the alternator.

Prevention Tips:

- Regularly check and replace serpentine belts and bearings as needed.

- Keep the engine and alternator clean to reduce heat buildup.

2. Electrical Overloads

Electrical systems in modern vehicles are complex and often involve multiple components running simultaneously. If an electrical overload occurs—like running high-power accessories (lights, audio systems)—it can lead to overheating and failure of the alternator. An overloaded alternator may work harder than it is designed for, leading to premature failure.

Prevention Tips:

- Avoid using excessive electrical accessories while the engine is idling.

- Ensure proper installation of aftermarket electronics by a professional.

3. Faulty Voltage Regulator

The voltage regulator is a crucial component that manages the electrical output of the alternator. If it fails, it can lead to either overcharging or undercharging of the battery. Overcharging can cause the battery to swell and eventually burst, while undercharging can lead to a dead battery and inadequate power supply for the electrical systems.

Prevention Tips:

- Regularly test the voltage output during maintenance checks.

- Replace any faulty components related to the voltage regulator immediately.

4. Corroded or Loose Connections

Corrosion on the battery terminals or loose connections can impede the flow of electrical current. Increased resistance can cause the alternator to work harder, ultimately leading to its failure. This is often noticeable through dimming lights or intermittent electrical performance issues.

Prevention Tips:

- Regularly inspect and clean battery terminals and connections.

- Ensure all connections are tight and secure.

5. Extreme Weather Conditions

Harsh weather can have a detrimental effect on the alternator. For instance, extreme cold can strain the battery and the alternator’s components, while high temperatures can cause overheating. Additionally, moisture can lead to electrical shorts, further compromising the alternator’s efficiency.

Prevention Tips:

- Protect the vehicle from extreme weather conditions when possible.

- Consider using protective covers in extreme climates.

6. Aging and Wear

Like any other mechanical component, alternators have a finite lifespan. As they age, internal components may wear down, leading to reduced efficiency or complete failure. Typically, an alternator can last anywhere from 80,000 to 150,000 miles, but this can vary widely based on driving habits and maintenance.

Prevention Tips:

- Schedule regular maintenance checks, especially as the vehicle ages.

- Inspect the alternator for signs of wear during routine vehicle inspections.

7. Belt Issues

The serpentine belt connects the engine to the alternator, driving its operation. If the belt becomes loose, worn, or breaks, the alternator will no longer function effectively. Symptoms of belt issues can include squealing noises or warning lights on the dashboard.

Prevention Tips:

- Inspect the serpentine belt for wear and replace it according to the manufacturer’s recommendations.

- Check tension regularly to ensure it isn’t too loose or tight.

8. Poor Quality Replacement Parts

When replacing an alternator, using low-quality parts can lead to early failure. Aftermarket parts may not meet OEM (original equipment manufacturer) standards, which can result in compatibility issues and reduced lifespan.

Prevention Tips:

- Always choose high-quality or OEM parts when replacing the alternator.

- Work with reputable mechanics who provide warranties on their work.

Signs of Alternator Failure

Being able to identify the signs of alternator failure early can help prevent further issues and costly repairs. Here are some common indicators:

-

Dimming or Flickering Lights: If the headlights or dashboard lights are dim or flickering, it may indicate alternator problems.

-

Warning Lights: The battery warning light on the dashboard is a clear indicator that there may be an issue with the alternator.

-

Electrical Failures: If electrical components are malfunctioning, such as power windows, radio, or dashboard displays, it can point to alternator issues.

-

Strange Noises: Any grinding, whining, or rattling noises coming from the alternator can indicate bearing failure.

-

Difficulty Starting the Engine: If the vehicle struggles to start or the engine stalls frequently, it might be due to insufficient power from the alternator.

Troubleshooting Alternator Issues

If you suspect your alternator is failing, it’s essential to act quickly. Here are some steps for troubleshooting:

-

Check the Battery: Sometimes, the battery may be the source of the issue. Test the battery’s voltage to ensure it’s functioning properly.

-

Inspect Wiring and Connections: Examine all connections leading to and from the alternator for corrosion, melting, or fraying.

-

Test the Alternator: Utilize a multimeter to check the voltage output of the alternator. A healthy alternator should produce 13.8 to 14.2 volts while the engine is running.

-

Listen for Unusual Noises: Identify any strange sounds when the engine is running, which could provide clues about the alternator’s condition.

-

Consult a Professional: If you cannot diagnose the problem, it’s best to take the vehicle to a qualified mechanic for an in-depth inspection.

Conclusion

The alternator plays a crucial role in maintaining a vehicle’s electrical system, and understanding the common issues that lead to its failure can help vehicle owners take preventative measures. Regular maintenance, prompt identification of symptoms, and quality replacement parts can go a long way in ensuring that your alternator—and your vehicle—remain in optimal working condition. Being proactive not only saves time and money but also enhances overall vehicle reliability and safety. By staying informed and vigilant, vehicle owners can eliminate many of the risks associated with alternator failure.